This Indian Man Recycles Disposable Face Masks Into Building Bricks

Brick 2.0 is ready to use for building,

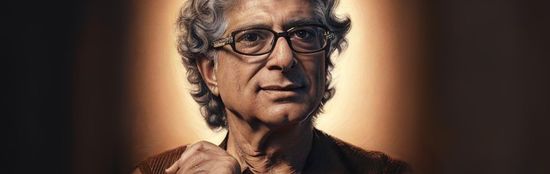

Everyone knows that face masks and protective gear save lives. But what happens to all of them after people are done using them? That’s a question that many people are asking. Binish Desai, 27, the founder of Eco-Eclectic Technologies, in Western India is one of them.

When Desai saw the collateral impact of the coronavirus pandemic due to the rising use and demand for single-use masks and gear, he decided he had to do something, according to The Hindu. So, he created a way to prevent tons of disposable Personal Protective Equipment (PPE) from being discarded and ending up in landfills or water streams. He calls it Brick 2.0.

“Initially, everyone was talking about how the lockdown had helped reduce pollution, but I could only think of what the rising demand for PPE suits and masks would lead to,” Desai told The Hindu.

The concern is more than justified. A study published by the American Chemical Society suggests that 129 billion face masks are used monthly during the COVID-19 pandemic, which causes great environmental contamination. In India alone, over 18.000 British tonnes of coronavirus related biomedical waste was generated in just four months between June and September, according to Benga Swash India.

So even when PPE is essential for medical use, it is extremely necessary to assess new alternatives and to intensify awareness regarding its proper use and disposal. Known as The ‘Recycle Man of India’ and featured in the Forbes ‘30 Under 30’ Asia 2018 list of successful social entrepreneurs, Desai’s latest invention brings recycled bricks enterprise to new heights.

The new version of the brick made from industrial paper and gum waste, now also includes shreds coming from face masks and protective suits. Otherwise, all that polypropylene plastic would go to waste taking hundreds of years to degrade, according to the magazine Waste Advantage.

The process starts with the collection of PPEs through eco bins installed in small shops and apartment buildings, with easy access for people to discard their used items. According to the Seattle Times, once in the factory, the fabric is isolated for 72 hours for safety reasons. Then it is sanitized and shred before being mixed with industrial paper waste and binder. Last but not least, the material is pressed by hand into different molds and once dry, each brick is ready to use.

“The new variant, Brick 2.0, is stronger and more durable, which makes it three times stronger than conventional bricks at twice the size and half the price,” Desai told The Hindu.

Desai’s innovation is not the only one aimed to re-use coronavirus waste and reduce its impact on the environment. French start-up Plaxtil also recycles face masks to turn them into material that can be molded like normal plastic. Currently, the company is creating new items used in the fight against the coronavirus, although the outcome could be used for other products and purposes as well.

In a complex scenario like the one we are living in these days; such recycling efforts may seem small. However, these solutions are not only relatively easy to scale, they are also very tangible in the short-term, which can really help humanity overcome today’s global environmental challenges. And what better metaphor than the one of the bricks: a solid means through which to build new and promising foundations for the day after tomorrow.

YOU MIGHT ALSO LIKE:

Sweden is Recycling so Much That the Country's Running Out of Trash

5 Ways You Can Calculate How Much Plastic Waste You Generate in a Year

Indian Startup Makes Tree-Free Paper That Saves Water Too